Our Products

Inflatable clamps provide uniformed controlled pressure to firmly clamp or bond products together.

Inflatable actuators are used to push a secondary seal (or fixture) into place in order to create a uniform, reliable seal.

Compression seals can be simple round shapes or highly complex designs using unique materials.

Our Industries

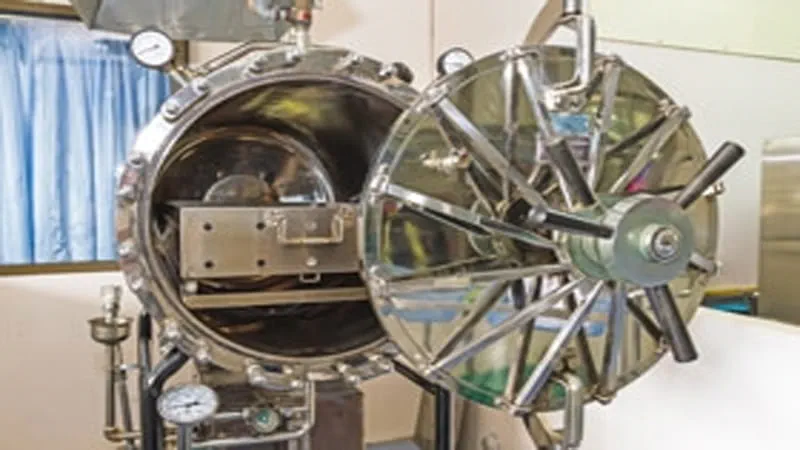

We develop specialty inflatable seals for glovebox isolators, tablet coaters, fluidized bed dryers, sterilizers, and freeze dryers.

Our industrial seals are the perfect fit for hoppers, valves, FIBC bulk bags, piston pumps, and rotary unions.

Applications include inflatable doctor blade actuators, conveyor brakes/stops, and inflatable shaft shutdown seals.

Industrial seals and gaskets ensure a safe environment in railcars, automotive test sheds, truck trailer roll up doors, and firetruck cabs.