An inflatable seal is a type of rubber seal which inflates (rather than compresses) to create an air or watertight barrier. When compared to elastomeric compression seals, inflatable rubber seals are more forgiving of irregular or misaligned surfaces, which boosts sealing integrity.

They are also easier to use because they require less force to ensure a good seal - just move the mating parts into place and inflate the seal to close the gap. This makes them the perfect solution for unique and/or difficult sealing applications.

Our inflatable seals are well suited for use with:

- Horizontal or vertical sliding doors

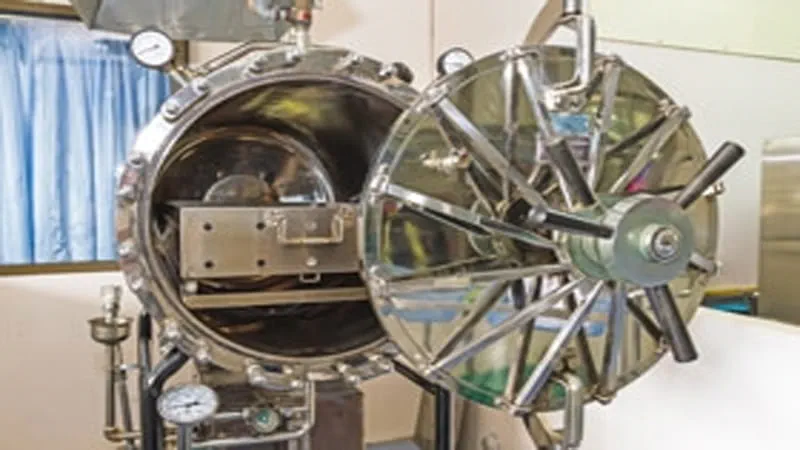

- Processing equipment where rapid sealing and unsealing is required

- Hinged doors with flush thresholds for easy personnel or equipment access

- Large fabricated doors or other closures where it is impractical to machine the sealing surfaces to accommodate conventional compression seals and gaskets

Have a sealing challenge? Contact us today to speak with one of our highly experienced Sales Engineers.

Custom and Standard Inflatable Seals for Any Application

Let our 70+ years of experience in the design and manufacture of unique sealing solutions work for your application. Start by selecting one our inflatable seal options below:

- Pneuma-Seal is our flagship line of inflatable seals. We offer over 70 profile designs (both extruded, non-reinforced and fabric reinforced) along with thousands of configuration and air connector options. If you need something completely custom or large (i.e. over 20 LF in circumference), then check out our Pneuma-Seal line of inflatable seals. Want to speak with someone now? Contact us today to get started.

Use Cases for Inflatable Seals

Our inflatable seals are being used today in environments where cleanliness and containment are paramount. Particularly interesting applications include:

- Kevlar® fabric reinforced inflatable EPDM rubber airlock seals to seal out radiation in nuclear power plants

- Low smoke silicone inflatable seals for sliding passenger doors on commuter trains

- USP Class VI (i.e. medical grade) inflatable seals for large pharmaceutical washing equipment

- Inflatable hopper seals used on powder handling equipment

- Large inflatable door seals (greater than 100 LF in circumference!) for aircraft hangers

Designing with Inflatable Seals

A successful inflatable seal design must take into account the environment it is used in, what it is sealing out (in), along with the operating pressures required to create an effective seal. Once this information is obtained, a good design must address:

- The seal configuration (i.e. where the seal will be installed, how it will inflate, and the overall size of the seal itself)

- The profile required in order to effectively seal the gap

- Use of the right material for the application, including the addition of fabric reinforcement when necessary

- Selection of the right air connector

For more information regarding proper seal designs, please review our “Designing with Inflatable Seals” guide or jump into our Technical Information section for further details. Want to speak with an expert? Contact us today to speak with one of our highly experienced Sales Engineers.